10 Health and safety topics to discuss on your toolbox talk

Knowing about health risks and taking steps to prevent them is the basis for a safer and healthier workplace. You can achieve this by having regular safety meetings.

These meetings give you a chance to raise awareness among your team about the specific risks they may encounter and reinforce safety protocols as needed. Having open discussions about these helps create a culture of safety where employees feel confident and protected while doing their jobs.

In this article, we’ve listed a bunch of health and safety topics that you can discuss during your toolbox talks, along with essential actions you can take to support your team.

What are five examples of health hazards?

In the workplace, there are certain hazards that can affect the health of your workforce. Here are five examples of health hazards to be mindful of:

- Chemical exposure: Working with or near hazardous chemicals, such as cleaning agents, paints, or solvents, can lead to respiratory problems, skin irritation, or long-term health issues.

- Noise pollution: Being exposed to loud noises from machinery, equipment, or construction sites can result in hearing damage, increased stress levels, and difficulty focusing on tasks.

- Physical hazards: These include risks like slips, trips, and falls, which can cause injuries ranging from minor bruises to severe fractures.

- Ergonomic issues: Poor ergonomics, like uncomfortable workstations, repetitive tasks, or improper lifting techniques, can contribute to musculoskeletal disorders, such as back pain, carpal tunnel syndrome, or strains.

- Biological hazards: Working in environments where there's a risk of exposure to infectious agents can cause illnesses, respiratory infections, or allergies.

Health and safety topic #1 - Slips, trips, and falls prevention

Slips, trips, and falls prevention focuses on avoiding accidents caused by slippery or uneven surfaces, which are more common than you might think. These incidents can lead to injuries ranging from bruises to severe fractures.

During your safety meeting, start by talking about the common causes of slips, trips, and falls in the workplace. Emphasize the importance of maintaining a clean and organized work environment and discuss the proper storage of equipment and materials to prevent tripping hazards.

Also, suggest practical tips on how to prevent slips, trips, and falls through good housekeeping practices. Encourage open communication during the meeting so everyone can share their experiences, concerns, and suggestions.

Discussing these workplace safety topics equips your team with the knowledge and understanding to perform safely around the workplace. But your job doesn’t stop there. When you’ve conducted your safety meeting, it’s important to take action to keep the workplace even safer.

Here’s what you can do after your toolbox talk:

- Make sure walkways are clear of obstacles so employees can move around safely.

- Use non-slip mats in areas prone to wetness or spills.

- Reduce the risk of tripping by improving lighting in dim areas.

- Encourage employees to wear appropriate non-slip footwear.

- Use clear signs to indicate wet or hazardous areas.

- Conduct regular inspections to identify and fix any uneven surfaces or potential hazards.

- Schedule training sessions on safe walking and proper use of handrails and use available safety learning tools to help with this.

Recommended courses about slips, trips, and falls prevention:

- Slips, Trips and Falls in Retail by EdApp

- Safety in the Workplace by EdApp

- Fall Hazards by EdApp

Sign up with EdApp and explore thousands of free editable safety courses today!

Health and safety topic #2 - Personal protective equipment (PPE) usage

Personal Protective Equipment (PPE) is the type of gear and clothing employees wear to keep themselves safe at work. Things like hard hats, gloves, goggles, and bright vests can help prevent injuries such as head bumps, hand cuts, and eye damage.

In your tailgate meetings, use this health and safety topic to teach your team how to use, take care of, and store their protective equipment properly. That way, they’ll learn what dangers the PPE protects them from and they can take charge of their own safety by consistently wearing and keeping their PPE in good condition.

Here’s what you can do after your toolbox talk:

- See to it that all your employees have the necessary PPE for their specific duties.

- Establish clear guidelines for using PPE consistently in the workplace.

- Keep an eye on compliance with PPE requirements and share reinforcement when needed.

- Regularly inspect and replace any PPE that’s damaged or worn out.

- Have emergency stockpiles of PPE accessible in case of unexpected situations.

- Conduct training for employees on the correct way to use and take care of their assigned PPE.

Recommended courses about PPE usage:

- PPE for Manufacturing by EdApp

- PPE for Construction by EdApp

- PPE for General Dentistry by EdApp

- Hand Safety for Construction by EdApp

- Airborne Hazards by EdApp

Health and safety topic #3 - Electrical safety and safe work practices

Talking about electrical safety is necessary in industries where employees come into contact with electrical equipment or systems. That includes industries like construction, manufacturing, utilities, maintenance and repair services, and healthcare.

During your safety meeting, teach your team the importance of proper wiring, grounding, and safe handling of electrical equipment. This knowledge is crucial in preventing electric shocks, burns, and other accidents.

Make sure they understand how and when to use the right tools and equipment for electrical work. Emphasize the importance of inspecting cords, plugs, and outlets for damage, and educate them about the hazards of overloading circuits.

Here’s what you can do after your toolbox talk:

- Inspect the workplace for electrical hazards, such as damaged cords, overloaded circuits, and faulty equipment.

- Secure proper installation, grounding, and maintenance of electrical systems and equipment.

- Mandate the use of appropriate PPE for electrical work at all times.

- Establish clear guidelines for the safe use of extension cords and electrical devices.

- Conduct regular electrical safety audits to maintain compliance and identify new hazards.

- Offer electrical safety training for safe electrical practices.

Recommended courses about electrical safety:

- Electrical Safety by EdApp

- Electrical Standards (Dentistry) by EdApp

Health and safety topic #4 - Machinery and equipment safety

Think about factories, construction sites, or even offices where printers and computers are used – all of these fall under machinery and equipment. From sharp tools to heavy equipment, these machines can cause serious accidents when they’re not used properly.

The importance of this health and safety topic lies in preventing injuries and accidents. In your safety huddles, teach your workers how to use these machines correctly, wear the right protective gear, and ensure machines are well-maintained.

Here’s what you can do after your toolbox talk:

- Regularly inspect all machinery for safety issues or wear and tear.

- Require the use of appropriate safety gear (e.g., helmets and gloves) while operating machinery.

- Keep all equipment in their best working condition through regular maintenance.

- Clearly mark areas with machinery and equipment for safety precautions.

- Make sure there’s always supervision when your new or inexperienced workers are using complex machinery.

- Train your workers how to use machinery correctly and safely.

Recommended courses about machinery and equipment safety:

- Safe Use of Machinery by EdApp

- Working Safely with Machinery by EdApp

- Handling Power Tools by EdApp

- Machine Guarding by EdApp

Health and safety topic #5 - Heat stress and hydration

Heat stress and hydration are vital aspects of health and safety, especially in workplaces where heat exposure is prevalent, such as construction sites or factories.

Excessive heat and humidity can lead to heat-related illnesses such as heat exhaustion or even heat stroke, which are severe and sometimes life-threatening conditions. To prevent these, proper hydration is needed. Staying hydrated helps workers maintain their body temperature and the energy to perform tasks effectively.

It’s important to note that talking about this topic isn’t just about giving comfort, but also largely about safeguarding their health even in challenging conditions.

Here’s what you can do after your toolbox talk:

- Make water stations accessible to all employees and encourage them to drink water frequently.

- Remind employees to take regular breaks in shaded areas, especially during hot hours.

- Advise wearing light, breathable clothing and hats to shield from direct sun exposure.

- Consider fans, cooling vests, or shaded rest areas to help employees cool off.

- Adjust work hours, if possible, to avoid the hottest parts of the day.

- Train employees how to recognize signs of heat stress and how to act promptly.

Recommended courses about heat stress and hydration:

- Working in the Heat by EdApp

- Sun Safety by EdApp

- Aviva: Managing Hot Work Operations by EdApp

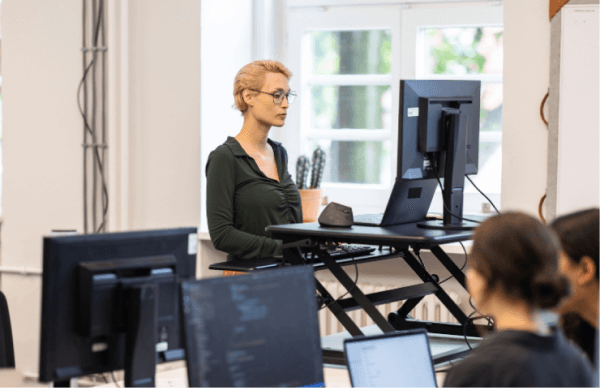

Health and safety topic #6 - Ergonomics and workstation setup

Workplace ergonomics is another important health and safety topic to discuss in your safety meetings. Here, you can share tips on how to set up work areas to make them more comfortable and efficient for everyone.

By talking about ergonomics, you can identify and fix things that might cause injuries, such as back pains or repetitive strain injuries. It can also result in reduced sick days and healthcare costs and improved the quality of work.

When employees are comfortable and physically sound, you can expect that they’ll also have a healthier and more productive mentality to get their job done.

Here’s what you can do after your toolbox talk:

- Offer adjustable chairs and desks that allow your employees to customize their workspace for comfort.

- Distribute ergonomic tools like cushioned mouse pads and keyboard rests.

- Adjust computer screens at eye level to prevent neck strain.

- Position keyboards and computer mice at a comfortable height.

- Remind your team to take short breaks and engage in stretching or movement exercises.

- Train them on proper sitting and standing posture and body mechanics.

Recommended courses about ergonomics and workstation setup:

- Ergonomic for Manufacturing by EdApp

- Ergonomics for Retail by EdApp

- 5 Minute Desk Exercises by EdApp

Health and safety topic #7 - First aid and CPR

First aid is the immediate care given to someone who’s injured or sick until professional medical help arrives. On the other hand, cardiopulmonary resuscitation (CPR) is a specific type of first aid used to revive someone whose heart has stopped or who has stopped breathing.

In the workplace, accidents and medical emergencies can happen at any time. Knowing how to give immediate help can greatly increase the chances of survival and reduce the severity of injuries or illnesses.

Using this health and safety topic as part of your OSHA toolbox talks can promote a sense of safety and readiness among your employees. It’ll give them the confidence to respond well in emergencies and not only help their coworkers in need but also those around them. That includes their family, friends, and even strangers who might need help.

Here’s what you can do after your toolbox talk:

- Make sure every area has well-stocked first aid kits with essential supplies.

- Display emergency contact numbers visibly in the workplace.

- Conduct mock emergency drills to practice first aid and CPR responses.

- Install accessible Automated External Defibrillators (AEDs) in key areas.

- Identify and train specific employees as designated first aiders.

- Offer refresher courses following OSHA standards to keep their first aid and CPR skills up-to-date.

Recommended courses about first aid and CPR:

- The Basics of First Aid by EdApp

Health and safety topic #8 - Hazardous materials handling

Hazardous materials can be anything from chemicals and gasses to flammable and toxic substances. Mishandling or improper storage of these substances can result in harmful exposure, or at worst, severe consequences like fires, explosions, or chemical spills.

When it comes to workplace safety, it’s important that your workers understand the safe handling, storage, and disposal of hazardous materials. This knowledge allows them to identify potential risks, use proper PPE, and follow the right protocols for risk mitigation. They’ll also be able to protect their own well-being, as well as that of their colleagues and the environment.

Here’s what you can do after your toolbox talk:

- Clearly label all hazardous materials with proper signs and symbols.

- Store hazardous materials in designated areas away from incompatible substances.

- Supply the appropriate safety gear such as gloves and masks.

- Conduct routine checks to make sure containers are intact and materials are stored securely.

- Maintain easily accessible material safety data sheets (MSDS) for all hazardous substances.

- Schedule regular training sessions on safe handling procedures.

Recommended courses about hazardous materials handling:

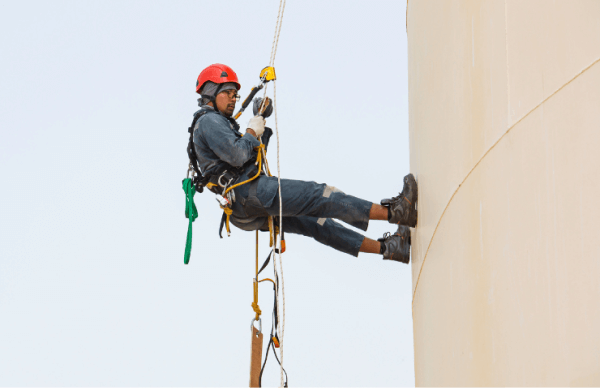

Health and safety topic #9 - Working at heights

Working at heights refers to any task or activity that takes place at an elevated location, such as on ladders, scaffolds, roofs, or elevated platforms.

In construction, it’s one of the most important safety meeting topics that you can talk about with your workers. Raise awareness about the proper use of appropriate fall protection equipment like harnesses, guardrails, or safety nets and address the hazards associated with falls.

Safety talks allow for an opportunity to educate your employees on safe work practices, such as maintaining three-point contact when climbing ladders. They can learn the proper techniques for ascending or descending elevated platforms and the best ways to avoid overreaching or leaning over unprotected edges.

Here’s what you can do after your toolbox talk:

- Assess the worksite for fall hazards and implement controls.

- See to it that your workers use proper fall protection equipment.

- Create clear protocols for working at heights, including briefings and hazard assessments.

- Regularly inspect and maintain height-related equipment.

- Conduct safety audits to improve compliance and identify areas for enhancement.

- Train employees on safe practices for ladders, tools, and three-point contact.

Recommended courses about working at heights:

- Working at Heights by EdApp

- Ladder Safety by EdApp

- Harnessing by EdApp

- Scaffold Safety by EdApp

- Aerial Lifts by EdApp

Health and safety topic #10 - Food safety

Food safety is the practice of handling, preparing, and serving food in a manner that’s safe for consumption. Mishandled or improperly prepared food can lead to contamination and foodborne illnesses, which can cause health issues among the workforce and customers alike.

This aspect of workplace safety is crucial as it directly impacts the health and well-being of employees and customers. Understanding and implementing food safety protocols in the workplace not only safeguards the health of your staff but also upholds the reputation of your business.

Here’s what you can do after your toolbox talk:

- Highlight the importance of storing food at the correct temperatures to prevent bacterial growth.

- Regularly monitor and record food temperatures, especially for perishable items.

- Educate your staff about preventing cross-contamination between raw and cooked foods.

- Stress the need for frequent handwashing among employees handling food.

- Implement strict cleaning schedules for kitchen surfaces and utensils.

- Conduct routine checks to secure compliance with food safety standards.

- Have frequent training sessions on food safety practices for all your kitchen staff.

Recommended courses about food safety:

- Food Safety Standards by EdApp

- Food Safety Hazards by EdApp

- Food Safety & Document Control by EdApp

- Food Poisoning (Foodborne Illnesses) by EdApp

- Food Contamination by EdApp

- Introduction to HACCP by EdApp

Author

Ella Mar

Ella is a content writer for EdApp, an award-winning e-learning management system designed to help companies deliver high-quality workplace training. In her free time, she enjoys painting, reading, or playing with her cat.