10 CNC Training Courses

We’ve carefully selected a list of CNC training courses designed to help manufacturing and industrial workers understand basic CNC machining and ensure safe operations on the worksite. The courses delve into topics such as machine safety, CNC lathes, CNC drilling, malfunction response, control panel functions, and machine setup.

1. Computer Numerical Control (CNC) Machining

Computer Numerical Control (CNC) Machining is a comprehensive CNC training course by EdApp that offers manufacturing workers with a basic understanding of computer numerical control machines and how they’re used.

The course starts by introducing the computerized system and its evolution from the old numerical control machines to the current equipment. It then delves into the different types of CNC machines, which include CNC milling machines, CNC turret lathes, CNC drilling machines, CNC plasma cutters, and CNC grinding machines. The last lesson quickly touches on CNC drilling machine operations and safety protocols with a drill press.

By the end of this course, workers are expected to understand how CNC lathe components operate and create precise parts safely and consistently.

Import this course for free directly from EdApp’s course library. And with their course creator tool, you can even customize the entire course to give a more engaging learning experience for your workers.

- Cost: Free (up to 10 users)

- Scope: CNC uses, types of CNC machines, CNC machining process and elements, CNC history, CNC drilling machine safety

Created by EdApp

Explore the course

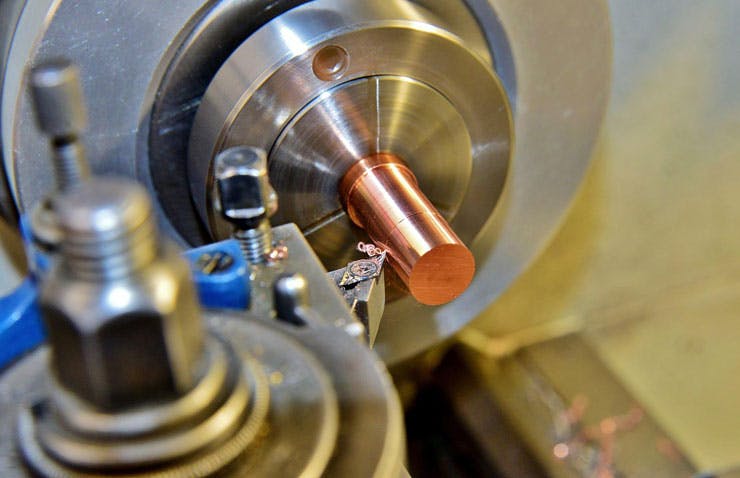

2. Basics of the CNC Lathe 211

Tooling University’s Basics of the CNC Lathe 211 course is a specialized training program designed for CNC lathe operators and supervisors. It mainly focuses on the components and functions of both the chucker and bar machine CNC lathe varieties.

Some of the topics covered in this CNC lathe training course include the types of CNC lathes, common components of CNC lathes, cutting variables, and more. Overall, the intermediate course has a total of 15 lessons, and once learners have completed the entire program, they’ll be eligible for both the CNC Lathe Operations and CNC Turning Programming, Setup & Operation certifications.

- Cost: Available upon request

- Scope: CNC lathes, components of CNC lathes, cutting variables, inner and outer diameter operations, cutting tools, tool holders, CNC lathe workholding

Created by Tooling University

Explore the course

3. Control Panel Functions for the CNC Lathe 251

Control Panel Functions for the CNC Lathe 251 is another lathe training course developed by Tooling University. The course delves into operator responsibilities, CNC control panels and control display, manual control modes, MDI and single block mode, and basic lathe controls. It also highlights other technical aspects of CNC lathe operation.

All in all, the course is divided into 18 lessons. Workers who complete the training program are qualified to receive CNC Lathe Operations, CNC Turning Programming, Setup & Operation, CNC Turning: Programming, Setup, and Operations-FastTrack certifications.

- Cost: Available upon request

- Scope: CNC control panels and control display, manual control modes, MDI and single block mode, and basic lathe controls, overrides, optional stop and block delete, turret indexing, chip conveyor, proving out

Created by Tooling University

Explore the course

4. CNC Machine Operator Training Program

Amatrol’s CNC Machine Operator Training Program will offer aspiring CNC machine operators with the technical training they need to be able to set up, inspect, operate, and maintain CNC machines effectively. The course goes into detail about different subtopics like part measurement and gauging, CNC interfacing, tooling decision-making, and machine malfunction response. As workers progress through the lessons, they’ll also learn more about the proper protocols for setting up and operating CNC machines.

The best part about this course is that Amatrol incorporates multiple elements, such as animations and narration to engage learners with different learning styles.

- Cost: Available upon request

- Scope: Part measurement and gauging, CNC interfacing, tooling decision-making, and machine malfunction response

Created by Amatrol

Explore the course

5. CNC Machining Short-Term Training Program

Offered by Hawkeye Community College, the CNC Machining Short-Term Training Program is a condensed CNC training course that’s perfect for entry-level CNC machine operators or general machinists. It focuses on all the basics of CNC machining, including machine setup, operation, parts inspection, and production runs. Through the course, workers will gain more knowledge and hands-on experience with blueprint reading as well as precision measurement and gauging.

To earn a non-accredited certificate of completion, individuals must attend 80% of all scheduled classes and get a grade of 80% on all course materials.

- Cost: $2,859 USD

- Scope: CNC machine set up, operation, parts inspection, production runs, blueprint reading, precision measurement and gauging, turning and milling processes, mill and lathe programming and operation

Created by Hawkeye Community College

Explore the courseExplore our library including CNC training courses

6. CNC Manufacturing Training

Broward College’s CNC Manufacturing Training course talks about how machinists can program CNC machines to produce precise components used in a variety of products. This advanced CNC training course also helps learners gain a better understanding of the programming involved in directing an automated CNC machine.

Learners will have the benefits of online learning and in-person training. No need to look for "CNC training near me" as they can take this online. And once they pass their training, they’ll be able to receive nationally recognized industry certifications from the National Institute for Metalworking Skills (NIMS) and the Manufacturing Skills Standards Council (MSSC).

- Cost: Request information

- Scope: Programming CNC machines like lathes, mills, routers, and grinders

Created by Broward College

Explore the course

7. Machining Center Programming, Setup, and Operation

With FANUC America Corporation’s course on Machining Center Programming, Setup, and Operation, industrial workers and general machinists will learn how to safely handle CNC machines. The topics discussed in this CNC training course will build their knowledge of production setup and completion as well as G-code programs, also known as manual programming.

Before you consider this 30-hour training program for your workers, keep in mind that they need to complete the recommended pre-requisites, which include shop safety, shop math, and more. One of the biggest perks of this course is that FANUC America Corporation offers customized classes that can be brought directly to your facility.

- Cost: $750 USD per student

- Scope: Production setup and operation, G-code programs a.k.a. manual programming

Created by FANUC America Corporation

Explore the course

8. Computer Numerical Control (CNC)

Midlands Technical College offers a specialized CNC training course called Computer Numerical Control (CNC), which is tailored for aspiring CNC machine operators and programmers. Some of the topics covered in this course include blueprint reading, precision measuring tools, the functionality of CNC machine components, and CNC programming.

Unlike other skill based training courses, this online program also offers workers with basic working knowledge of vertical mills and machining lathes. By the end of this training program, they'll be able to enter instructions to program machinery, maintain equipment, and follow safety regulations.

- Cost: Request a quote

- Scope: Blueprint reading, precision measuring tools, the functionality of CNC machine components, and CNC programming, knowledge of vertical mills and machining lathes

Created by Midlands Technical College

Explore the course

9. Basics of CNC Programming & Machining

Simon Fraser University designed the Basics of CNC Programming & Machining course for anyone who wants to develop foundational CNC machine operation skills. The training program delves into the history of CNC machines and their different categories. It also discusses basic concepts of CNC programming using CAM software, 3D toolpaths, G-codes, and M-codes.

In the final assessment, students will be required to CNC program a given exercise, but anyone who misses in-person classes will not be allowed to work on the machine at any level.

- Cost: $900 USD

- Scope: History of CNC machines, CNC machine categories, basic concepts of CNC programming using CAM software, 3D toolpath, G-codes, and M-codes

Created by Simon Fraser University

Explore the course

10. CNC Machinist Training

Developed by Northwest Missouri State University, the CNC Machinist Training program covers basic CNC topics such as workholding, shop math, machining, and stamping. It’s a fully online CNC training course that aims to help students master the fundamentals of CNC controls and programming, practice proper inspection methods and workholding principles, as well as understand metallurgy, machining, and grinding processes.

A huge advantage of this course is that it’s completely self-paced, allowing learners to go through the lessons at their own convenience.

- Cost: Enroll in the course

- Scope: Workholding, inspection, shop math, machining and stamping, quality and manufacturing management, metal cutting, grinding, fundamentals of CNC controls and programming, inspection methods

Created by Northwest Missouri State University

Explore the courseGet a good grasp of CNC machine operation with CNC training courses

CNC machines play an integral role in the manufacturing industry. They're often used to create important everyday items like electrical components, automobile interiors and exterior. They're also used to build original equipment prototypes, building models, and heavy-duty parts for household appliances, boats, trains, aircraft, and spacecraft. Operating these machines requires in-depth technical knowledge and proficient skills that are only acquired through proper CNC training. Through in-person and online training programs, your workers will be able to gain more CNC machining and programming experience, giving them the confidence to carry out their tasks safely and effectively. To help you provide top-tier training to your employees, make the most of the CNC training courses we’ve listed above.